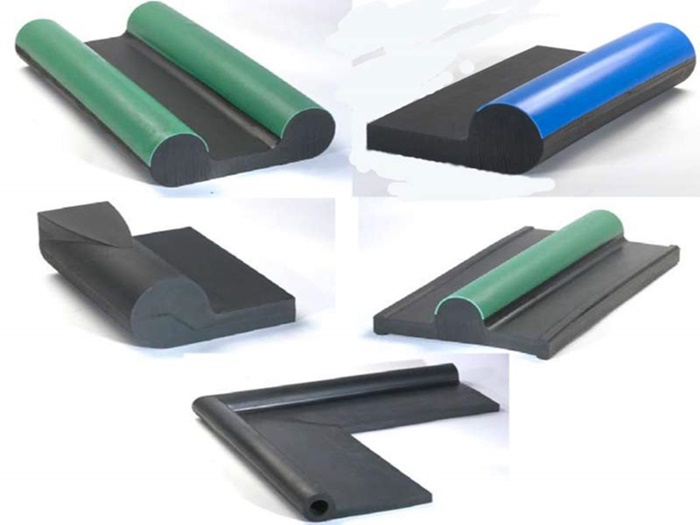

The Rubber Company manufactures rubber gaskets from a wide range of materials kept in stock. We keep many different grades of rubber sheeting used to produce rubber gaskets and seals. From standard grade rubber sheeting to high temperature resistant sheeting to food quality rubber sheeting.

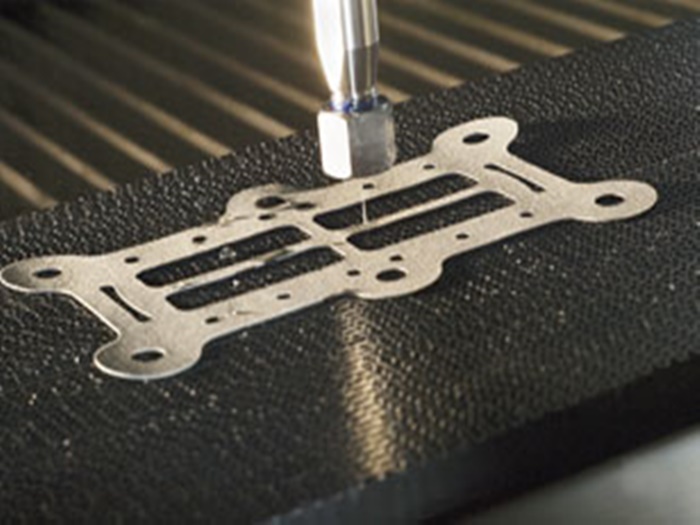

We are able to produce rubber gaskets using various processes including die cut gaskets, water-jet cut gaskets and hand fabrication.

The Rubber Company keep various different solid rubber and sponge rubber materials in stock for producing rubber gaskets. Rubber gasket materials include: Neoprene rubber, Nitrile rubber, EPDM rubber, Butyl rubber and Silicone rubber.

Rubber gaskets can be produced with self-adhesive backing or plain back.

The gaskets application is used to decide what material and grade is required. We can always advise on most suitable material if you are unsure what is best.

The Rubber Company supply rubber gaskets to an array of industries including: marine, automotive, engineering, defence, food industry, mining, electrical.